Honeywell officially announced its white paper entitled "Smart Manufacturing for China's Process Industry: From Insights to Outcome" at the 2019 Tech Summit, which took place in Xi'an during October 16-18. The success story of Sennics as a smart factory was featured in the white paper. Tang Wenlei, Assistant President of Sennics, attended the conference and delivered a keynote speech entitled "Leading Capabilities, Great Services, Innovative Models--Empowering Smart Sennics with Digital Technologies". After that, she accepted media interviews at the press conference.

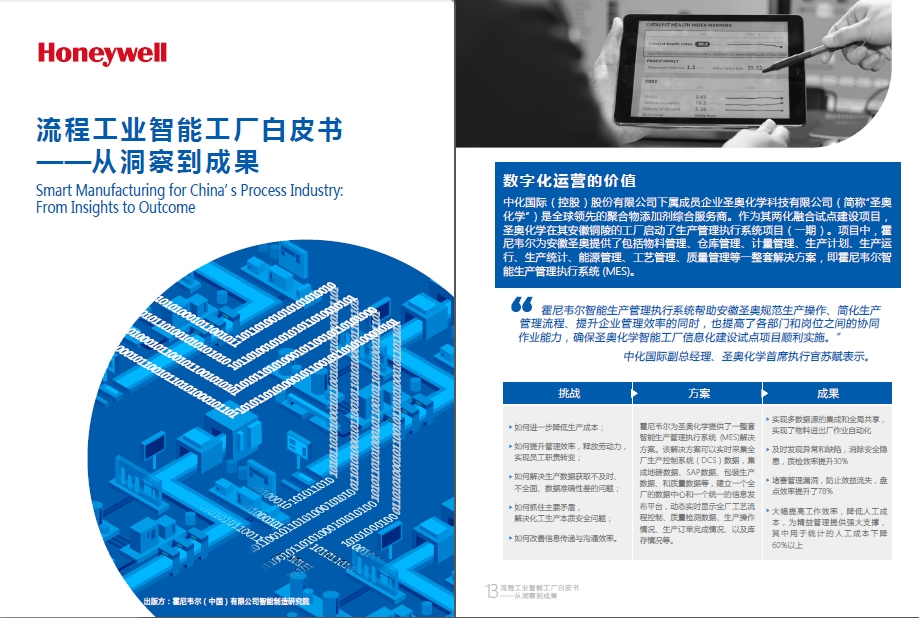

The white paper entitled "Smart Manufacturing for China's Process Industry: From Insights to Outcome" mainly includes the definition of "smart factories", the key success factors of smart manufacturing, the latest technological trend in smart manufacturing, as well as the case studies of Honeywell using advanced technologies to help Chinese and global customers achieve success. Sennics as a case study of a successful smart factory in the white paper with respect to the actual application of "the value of digital operations" shared its insights with customers.

There were also a series of panel sessions during the summit forum. Tang delivered a keynote speech entitled "Leading Capabilities, Great Services, Innovative Models--Empowering Smart Sennics with Digital Technologies" at the panel session "Industrial Internet & Smart Manufacturing". She shared the path and experience of Honeywell using its smart technologies to help Sennics build smart factories. Facing the challenges and opportunities arising from issues with manufacturing efficiency, Sennics follows its core value of "In Science We Trust" and jumps at the strategic opportunities to reduce costs, increase efficiency and improve the smart manufacturing capability by building a multiple-level integrated information platform, constantly optimizing organizational structures and business processes, driving management transformation, using digital technologies to innovate with customer service models, actively pursuing digital transformation, and building a production management platform centered on the MES system. Tang also briefly introduced Sennics' overall digital strategy for the future. The company will focus on creating a "Smart Sennics" to leverage digitization to drive the company's technological progress and innovative development and eventually maximize the value for customers by building "smart factories" as an important path towards management upgrading and strategic leaping.

On October 17, Tang and Sinochem International's IT GM Xie Xudong accepted the interview by "Control Engineering of China" and Jzgkchina.com. She said that Sennics is building IT systems as the important support for management upgrading and strategic leaping, and has been increasing investments in IT initiatives in recent years in response to the call for "industrialization-informatization integration". With the completion of the automation initiative and the successful deployment of Honeywell's Manufacturing Execution Systems (MES)-Phase-I, Sennics Anhui, which is a factory of Sennics, not only realized efficient production operation management and smart production, but also, more importantly, comprehensively improved its operational capability and profitability. This helps to realize the digital transformation. After the system was launched, Sennics Anhui achieved automatic operation for moving materials in and out of the site, the quality testing efficiency was increased by 30%, the inventory taking efficiency was increased by 78%, and the labor cost for taking statistics was reduced by more than 60%.